Calendering Machines: Forging The Future Of Pvc Fabric Lamination

Share Post

In a diverse landscape of technologies, calendaring machines emerge as a powerhouse, especially when it comes to producing strong, high-performance PVC-laminated fabrics. While other methods, such as knife coating, which applies liquid PVC paste, and hot melt coating, which uses molten polymers, calendering operates on a unique principle: directly forming a PVC film and then fusing it to the fabric. This unique approach offers several compelling advantages that establish it as a preferred choice for demanding applications, making it a cornerstone of success in the technical textiles industry.

The calendering process is a marvel of precision engineering. It begins not with a liquid, but with a highly viscous, dough-like PVC compound, a carefully formulated mixture of PVC resin, plasticizers, stabilizers, pigments, and other additives. This compound is fed into a series of huge, heated, and highly polished steel rollers called calendar rolls. These rolls, arranged in various configurations (L-type, inverted L-type, Z-type, etc.), gradually squeeze and flatten the molten PVC into a continuous, uniform film of precise thickness. Crucially, as this PVC film is formed, a fabric substrate is simultaneously inserted into the calendar stack, often entering the final nip (the point where the last two rollers meet). Here, under extreme heat and pressure, the freshly formed PVC film is pressed directly onto and into the fabric weave, creating an incredibly strong and integral laminate.

Calendering machines for PVC fabric lamination have numerous and profound advantages that set them apart from other coating methods. One of the most significant is their ability to produce thicker, stronger fabrics. While knife-applied coating can create layers, calendering inherently excels at creating dense, hig h-ounce weight materials with exceptional tear and tensile strength, making them ideal for applications demanding extreme durability.

h-ounce weight materials with exceptional tear and tensile strength, making them ideal for applications demanding extreme durability.

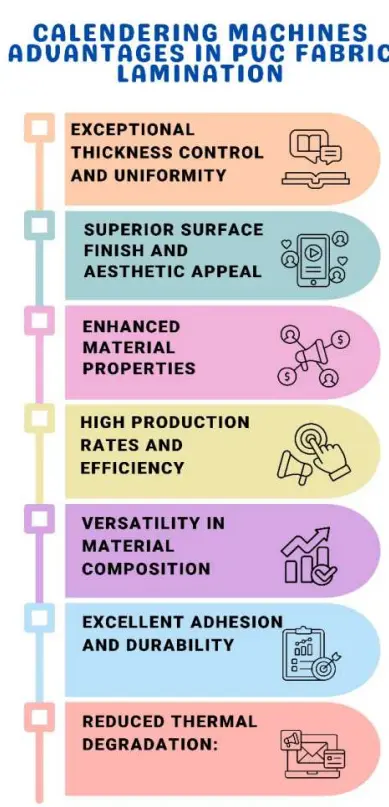

Think of the robust materials used for truck tarpaulins, large-scale flexible structures, high-performance geomembranes, or industrial conveyor belts – these are often the domain of calendering. Additionally, calendering provides unmatched control over thickness and uniformity. The precise spacing between the polished rollers ensures uniform film thickness across the entire width of the fabric, minimizing variations that could compromise product integrity. This precision, combined with high pressure, also provides excellent material consolidation and low porosity, resulting in a more impermeable and durable surface. This is crucial for waterproof applications and those requiring a strong barrier against chemicals or contaminants. The process also allows for simultaneous double-sided coating or lamination, often in one pass, which can significantly increase production efficiency compared to methods that may require multiple or separate coating and lamination steps.

Beyond the technical merits, calendering contributes significantly to the commercial success of PVCcoated fabrics. The inherent robustness and longevity of calendered materials translate into products with extended lifespans, reducing replacement costs for end-users and building a reputation for quality for manufacturers. The ability to directly impart textures and patterns onto the PVC surface through engraved calender rollers also offers immense design flexibility, allowing for the creation of synthetic leathers, decorative wall coverings, or non-slip flooring with precise aesthetic and functional properties. While the initial investment in calendering machinery can be substantial due to the sheer size and engineering complexity of these systems, their high throughput, consistent quality, and the high-value products they create often lead to a rapid return on investment.

While knife coating offers flexibility for varying coating weights and hot melt coating champions speed and solvent-free operation, calendering machines remain indispensable for their ability to produce exceptionally thick, durable, and uniform PVC-laminated fabrics. Their robust construction, precise control over material properties, and capacity for high-volume production make them the undisputed champions for heavy-duty applications where performance and longevity are paramount. As industries continue to demand tougher, more reliable, and visually appealing technical textiles, the calendering machine will undoubtedly remain a vital and successful technology in the PVC coating landscape.

03:03 PM, Oct 17

Source : Calendering Machines: Forging The Future Of Pvc Fabric Lamination

Rieter Issues Market Update on Completion of Barmag Acquisition

10:33 AM, Dec 20