Hot Melt Coating Machines: Revolutionizing PVC Fabric Applications with Speed and Sustainability

Share Post

In the dynamic world of textile coating, Hot Melt Coating Machines, particularly when utilizing PVC-based hot melts, represent a significant leap forward. While traditional PVC fabric coating often relies on plastisol (a liquid dispersion that requires a chemical cure) or calendering of pre-formed PVC films, hot melt technology offers compelling advantages in terms of efficiency, environmental impact, and product versatility.

In the world of technical textiles, innovation is constant, and new technologies are always emerging to redefine efficiency, sustainability, and product performance. While traditional PVC coating methods like knife coating and calendering have long been the workhorses of the industry, a quieter revolution is taking place with the rise of Hot Melt Coating Machines for PVC-based materials. Often overlooked in discussions about conventional PVC plastisol application, these sophisticated machines are carving out a significant niche, offering distinct advantages that are proving to be highly beneficial and increasingly successful in specific applications, setting them apart from their older counterparts.

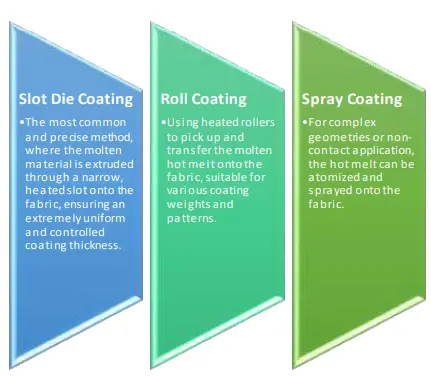

At its core, hot melt coating involves applying a thermoplastic material that melts when heated and solidifies rapidly upon cooling, forming a bond or a coating. Unlike liquid PVC plastisols, which are dispersions requiring a fusion (curing) process in an oven, PVC-based hot melts are solid at room temperature and do not rely on solvents or water. This fundamental difference drives their compelling benefits. The process begins with the PVC-based hot melt compound, typically in pellet form, being fed into a heated melting unit – often a precision extruder or melt tank. From there, this molten material is precisely metered and applied onto a moving fabric web using advanced slot dies, precision rollers, or sophisticated spray nozzles. The magic happens immediately as the coated fabric passes over cooling rollers, causing the hot melt to solidify almost instantly, forming a durable and flexible layer or an incredibly strong adhesive bond.

The success and growing adoption of hot melt coating machines for PVC-based applications stem from several key advantages that translate directly into business benefits. Firstly, their environmental superiority is a major draw. Since hot melts contain little to no volatile organic compounds (VOCs) or solvents, they eliminate the need for costly and energy-intensive solvent recovery systems and drastically reduce atmospheric emissions, making them a far greener choice. This not only aids in regulatory compliance but also enhances workplace safety and reduces the overall environmental footprint. Secondly, unparalleled efficiency and speed are hallmarks of these machines. The rapid solidification of hot melts means there’s no lengthy drying or curing oven required, leading to significantly higher line speeds and increased throughput.

This translates directly into higher production volumes and lower manufacturing costs per unit. Imagine the energy savings and the reduced factory floor space needed when you eliminate massive, heated drying tunnels. Furthermore, hot melt technology offers exceptional precision and versatility. Advanced slot die and gravure coating systems allow for incredibly uniform and thin coating weights, which is crucial for applications where material consumption needs to be minimized or specific performance characteristics are paramount. They can also handle a wider range of heat-sensitive substrates compared to high-temperature plastisol curing.

While traditional plastisols excel at creating very thick, robust coatings like those found on heavy-duty tarpaulins, hot melts shine in applications requiring thinner, more precise layers, or where immediate, aggressive bonding is needed, such as in high-performance textile laminates for automotive interiors, specialized protective apparel, or intricate adhesive applications. This niche, where flexibility meets efficiency and environmental responsibility, is where hot melt PVC coating machines are truly proving their worth, demonstrating that sometimes, the less common path can lead to the most beneficial and successful outcomes.

10:09 AM, Oct 17

Source : Hot Melt Coating Machines: Revolutionizing PVC Fabric Applications with Speed and Sustainability

Rieter Issues Market Update on Completion of Barmag Acquisition

10:33 AM, Dec 20