Polypropylene Building Blocks for Non-woven Agrotextiles

Share Post

In the evolving landscape of modern agriculture, nonwoven agrotech textiles have become an indispensable solution for enhancing crop yield, protecting plants, conserving resources, and promoting sustainable farming practices. Among the various raw materials utilized in the production of these textiles, polypropylene (PP) stands out as the most commonly used synthetic polymer due to its unique blend of cost-effectiveness, versatility, and performance characteristics.

Polypropylene is a thermoplastic polymer derived from the polymerization of propylene monomers, widely known for its lightweight nature, high tensile strength, resistance to moisture and chemicals, and excellent processability. These features make it ideally suited for agricultural applications such as crop protection covers, mulch mats, shade nets, root bags, and various other horticultural and agrotextile products.

Manufacturing Process of Polypropylene-Based Nonwoven Agrotech

The production of agrotech textiles, nonwoven textiles using polypropylene as a raw material, involves a technically intricate and scientifically grounded process that integrates principles from polymer science, thermomechanical engineering, and textile technology. The journey commences with the selection and preparation of polypropylene granules, which are derived from petroleum-based resources.

Polypropylene is preferred in the manufacturing of agrotextiles due to its lightweight nature, resistance to chemicals, hydrophobicity, high tensile strength, and cost-efficiency. To tailor the polymer for specific agricultural applications, the granules are often compounded with functional additives such as ultraviolet (UV) stabilizers to enhance durability under sunlight, antioxidants to inhibit oxidative degradation, flame retardants for safety, and masterbatches containing color pigments. These additives are uniformly blended with the base polymer using high-speed mixers to ensure a homogeneous feedstock for extrusion.

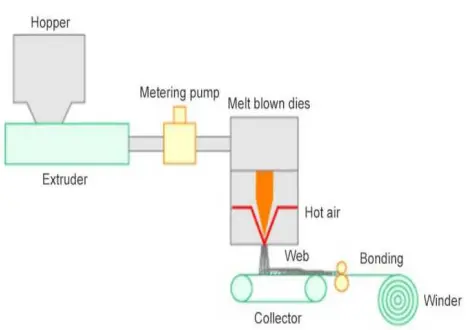

Once prepared, the compounded polypropylene granules are conveyed into an extruder, where thermal energy is applied to melt the polymer. The extrusion temperatures typically range from 160 °C to 280°C, and are carefully regulated across the extruder’s zones to ensure optimal viscosity and flow behavior of the molten polymer. The molten polymer is passed through a filtration system to remove any contaminants and then conveyed using a metering pump, which delivers a consistent and precise flow rate to the spinning assembly.

The polymer melt then enters the spinneret precision-engineered plate with hundreds of tiny holes through which it is extruded to form continuous filaments or fibers. Upon exiting the spinneret, these fibers are subjected to a cooling process using quenching air, which solidifies them rapidly and ensures controlled crystallization of the polymer chains. Following solidification, the fibers undergo a high-speed drawing process, also known as attenuation. This step utilizes aspirators or air jets to elongate the filaments, aligning the molecular chains and significantly enhancing the mechanical properties of the fibers, such as their tensile strength and elasticity. These drawn fibers are then deposited randomly on a moving conveyor belt to form a web. This web formation process is governed by aerodynamic laydown principles, where the orientation and distribution of fibers are controlled by air currents to create a uniform mat.

The random orientation of the fibers results in an isotropic structure, meaning the fabric exhibits similar strength and performance in all directions, which is advantageous for many agricultural applications. The web formed in this way is still in a loose, unbonded state, which necessitates consolidation through a bonding mechanism. In the case of spunbond nonwoven manufacturing, thermal bonding is the most commonly adopted technique. The web is passed between heated calender rollers, which apply heat and pressure to thermally fuse the fibers at their contact points. The rollers may have smooth or patterned surfaces, depending on the desired bonding characteristics. Point bonding, created using patterned rollers, results in fabrics that retain higher flexibility and breathability, whereas flat or area bonding increases the strength and stiffness of the fabric. This bonding process is critical not only to provide mechanical integrity to the nonwoven fabric but also to define its texture, porosity, and tensile behavior.

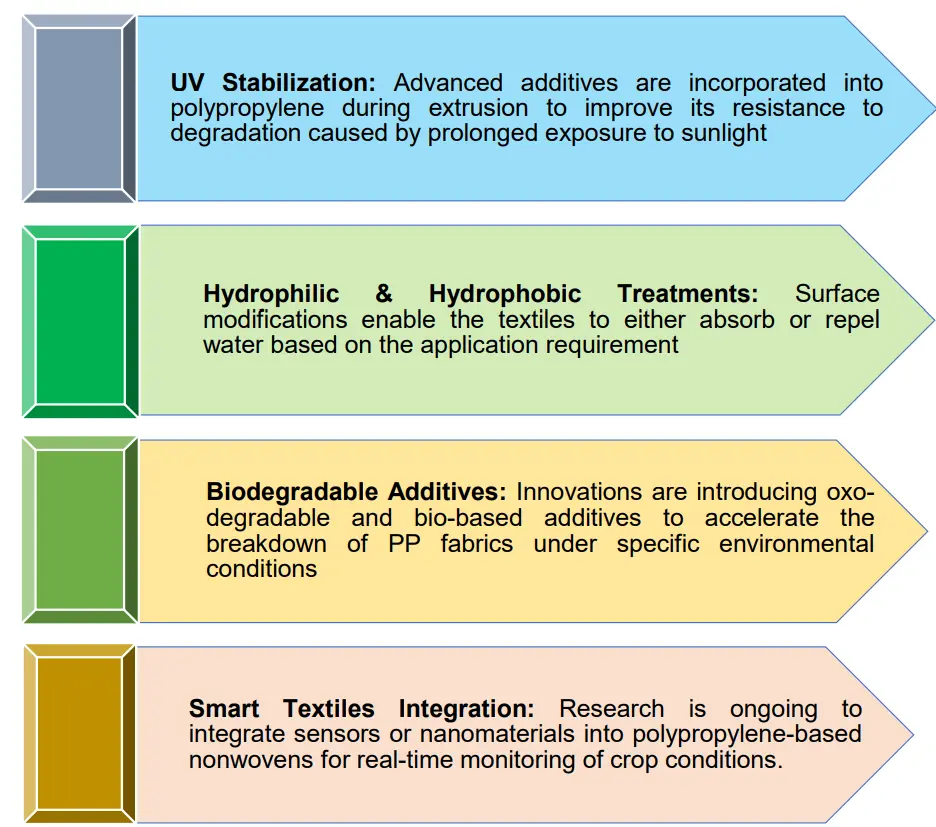

After bonding, the nonwoven material may undergo finishing treatments to enhance its functional properties. For agricultural applications, UV stabilization is a particularly important finishing process because these fabrics are often exposed to prolonged sunlight in open fields. This is achieved either by incorporating UV stabilizers into the polymer melt or by applying chemical coatings on the surface. In addition, hydrophilic or hydrophobic treatments may be applied to adjust the fabric’s water permeability depending on whether water absorption or repellency is desired. For example, mulch fabrics may need to be hydrophobic to prevent water loss, whereas crop covers may require hydrophilicity to allow water penetration. These functional finishes are applied using processes such as chemical dipping, spraycoating, or plasma treatment, which alter the surface characteristics of the Fibers without affecting the bulk properties.

The treated nonwoven fabric is then subjected to slitting and winding operations. Large fabric webs are slit into rolls of desired widths using precision cutting systems. These rolls are then tightly wound and packaged to prevent contamination and mechanical damage during transportation and storage. Quality assurance checks are carried out at this stage to assess fabric weight (GSM), tensile strength, elongation at break, pore size distribution, UV resistance, and dimensional stability. These quality parameters are essential to ensure the fabric’s suitability for its end use in agriculture.

In practical applications, these polypropylene spunbond nonwoven fabrics serve various agrotextile functions. They are used as crop covers to protect plants from pests, UV radiation, and frost while allowing air and moisture exchange, which helps maintain a favorable microclimate. In weed management, spunbond fabrics act as mulch films that block sunlight to suppress weed growth, reduce the need for herbicides, and retain soil moisture.

Additionally, these fabrics are employed in soil stabilization, erosion control, greenhouse shading, seedbed liners, and root control bags in nurseries. Their weight, durability, flexibility, and eco-efficiency make them ideal for temporary agricultural usage, especially when designed with biodegradability or recyclability in mind.

From a theoretical perspective, the success of this manufacturing process hinges on optimizing numerous parameters, including polymer melt flow index (MFI), spinneret design, filament draw ratio, web formation speed, bonding temperature and pressure, and finishing treatment chemistry. Each variable must be controlled precisely to produce a consistent, high-performance textile that meets the demanding requirements of agricultural usage.

Moreover, as the global demand for sustainable agricultural practices rises, research in the field is increasingly focusing on integrating environmentally friendly practices, such as using recycled PP, biodegradable polymer blends, and more efficient energy consumption during production. Furthermore, the inclusion of smart textile technologies, such as embedded sensors for monitoring soil humidity or plant health, is an emerging frontier in agricultural nonwovens, promising to revolutionize the role of technical textiles in farming.

Thus, the theoretical foundation and practical implementation of polypropylene spunbond nonwoven production for agricultural textiles represent a highly interdisciplinary field, merging polymer science, textile engineering, environmental science, and agronomy. By understanding the detailed mechanisms at each stage of the process, manufacturers can design agrotextiles that are not only cost-effective and functionally robust but also aligned with the growing need for sustainability and technological innovation in agriculture.

Technological developments have significantly enhanced the functionality and performance of polypropylene-based nonwoven agricultural textiles. The future of polypropylene-based nonwoven textiles in agriculture looks bright, especially as the industry moves towards more sustainable and efficient farming methods. With growing interest in precision farming, water conservation, and adapting to changing climate conditions, these textiles are becoming essential tools for modern agriculture.

Farmers and agri-businesses are increasingly turning to solutions that support automation and reduce environmental impact, and polypropylene nonwovens fit right into that shift. They’re already being used in a variety of ways, from creating controlled environments for crops and smart mulching systems to designing shade nets tailored for different plants and setting up temporary crop shelters and protective tunnels. As the global push for smart agriculture and food security continues, we can expect the use of these high-performance materials to grow rapidly across both developed and developing countries.

That said, sustainability remains a critical consideration. While polypropylene isn’t biodegradable, its long-lasting nature and versatility can actually contribute to more sustainable farming when used wisely. For starters, these nonwovens can be recycled and repurposed for secondary uses, helping to cut down on waste. They’re also lightweight and require fewer raw materials to produce compared to traditional woven fabrics, making them more resource-efficient. Products like mulch mats not only help conserve water by reducing evaporation also protect the soil and improve crop yields by acting as barriers against weeds and pests, cutting down the need for chemical pesticides. Plus, with UV-stabilized options, these textiles are made to withstand harsh field conditions for longer periods, reducing how often they need to be replaced.

The industry isn’t stopping there. There’s an active push to improve the environmental footprint of polypropylene through circular economy approaches, biodegradable blends, and better waste management practices. All in all, polypropylene nonwoven textiles are proving to be a smart, forward-thinking choice for agriculturesupporting both productivity and sustainability in the fields of tomorrow.

Polypropylene remains at the forefront of raw materials for nonwoven agricultural textiles due to its excellent balance of performance, affordability, and adaptability. While sustainability challenges exist, innovations in materials science and recycling practices are steadily transforming PP nonwovens into more eco-friendly solutions. As agriculture embraces modern methods for improved productivity and sustainability, polypropylene-based nonwoven textiles will continue to serve as a backbone for efficient, protective, and intelligent farming systems.

01:09 PM, Oct 13

Rieter Issues Market Update on Completion of Barmag Acquisition

10:33 AM, Dec 20